Understanding Overspray

What is Overspray?

In any pneumatic spray application, overspray is an area of concern that should be addressed early on. Fortunately if it does occur, it’s easily remedied through the use of a High Volume Low Pressure (HVLP) spray gun and operator training.

When we talk about overspray, we’re referring to any portion of sprayed material that doesn’t land on the target substrate, whether it lands beyond the border of the target substrate, or is dispersed into the air. Overspray results in wasted material, and effects the cleanliness of the spray area, so it’s logical to take the necessary steps to minimize it.

Using the Correct Equipment

Having the correct spray gun is the first, and most important step to take in minimizing overspray. SIMALFA HVLP Spray Guns allow spray operators to properly atomize the adhesive using low air pressure settings (most spray gun manufacturers offer similar HVLP models). Doing so will maximize product yield, eliminate waste, and help to keep the work environment clean.

The second important step is to install an air pressure regulator between your air compressor and each spray gun to prevent spray operators from adjusting atomization air beyond the desired setting.

Cleanliness Through Chemistry

SIMALFA revolutionized water-based adhesives with Overspray-Free Technology. While others have tried to control overspray via airless spray guns and expensive equipment, we recognized that this does nothing to eliminate operator variables. As a result, we chose to approach it through chemistry. This removes the reliance on precise spray gun settings and operator technique, which are the key contributors to overspray. Learn more about overspray free.

Causes + Solutions

Once we have the right equipment and a regulator in place, there are a few very simple steps we can take to eliminate overspray and waste. By making simple adjustments to the spray gun settings, and working with the spray operators on basic technique, we can all but eliminate overspray as a concern.

Detailed below are the 4 causes along with solutions for overspray.

Go to: SIMALFA {Overspray Free} Technology

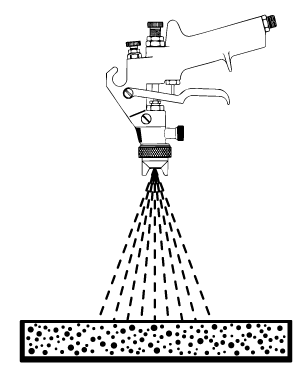

Air Pressure Too High {Spray Gun Setting}

CAUSE:

When using high air pressures a "bounce effect" and "cloud" will be created. Simalfa is naturally tacky and requires low air pressure for proper atomization.

SOLUTION:

Reduce Air Pressure

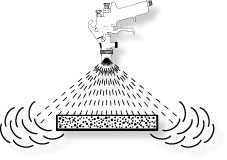

Spray Pattern Too Wide {Spray Gun Setting}

CAUSE:

We recommend a narrow spray pattern so the operator can better control the application of adhesive. A wide spray pattern will cause the operator to miss the substrate causing overspray and mess.

SOLUTION:

Reduce Pattern Width

Incorrect Angle of Spray {Operator Technique}

CAUSE:

It is recommended that the spray gun be held perpendicular (at 90 degree angle) to the substrate. As the angle decreases, the adhesive will "ricochet" off or miss the substrate causing overspray.

SOLUTION:

Spray at 90° Angle

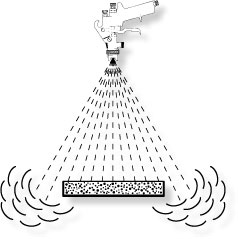

Spraying Too Far From Substrate {Operator Technique}

CAUSE:

The spray gun should be held at a distance between 4"-10" (10cm-25cm) from the substrate when applying Simalfa. As the distance between the spray gun and the substrate increases, so does the width of the spray pattern causing overspray.

SOLUTION:

Spray Closer to Substrate